Résumés

Abstract

This work aimed to study the possibility of using plant matter, Opuntia ficus indica juice (OFIJ), for conditioning the Beni-Messous (Algiers) wastewater treatment plant sludge. The optimum dosage of OFIJ was found to be 0.4 g⋅kg‑1 of dry matter, for which the residual turbidity, the dryness of the filtration cake, and the specific resistance of filtration were found to be 2.5 NTU, 24% and 0.13⋅1012m⋅kg‑1, respectively. The results obtained with OFIJ are also compared with those of commercial polyelectrolytes such as Chimfloc C4346, a cationic polymer, Sedipur NF 400, a non-ionic polymer, and Sedipur AF 102, an anionic polymer, and inorganic conditioners such as FeCl3 and Al2(SO4)3. OFIJ proved to be the most efficient because the optimum dosage was found to be 0.4 g⋅kg‑1 of dry matter for OFIJ whereas for Chimfloc C4346, FeCl3 and Al2(SO4)3 the optimum doses were be found to be 0.8, 80 and 60 g⋅kg‑1. Based on the obtained results, OFIJ could be used as a natural conditioner in sewage sludge treatment.

Keywords:

- Coagulation,

- filtration,

- Opuntia ficus Indica,

- sludge,

- conditioning

Résumé

Ce travail avait pour but d’étudier la possibilité d’utiliser un matériau naturel d’origine végétale, le jus de cactus Opuntia ficus indica (OFIJ) dans le conditionnement des boues résiduaires de la station de traitement des eaux usées de Beni-messous (Alger). À la dose optimale de l’OFIJ (0,4 g⋅kg‑1 de MS) la turbidité résiduelle, la siccité du gâteau de filtration ainsi que la résistance spécifique à la filtration (RSF) étaient respectivement de 2,5 NTU, 24 % et 0,13⋅1012m⋅kg‑1. Les résultats obtenus avec le jus de cactus ont été comparés à ceux obtenus en utilisant des polyélectrolytes commerciaux à savoir le Chimfloc C4346, Sedipur NF 400 et Sedipur AF 102, et les sels minéraux FeCl3 et Al2(SO4)3. Les doses optimales pour Chimfloc C4346, FeCl3 et Al2(SO4)3 étaient de 0,8, 80 et 60 g⋅kg‑1 de MS. Les résultats obtenus sont très encourageants afin de substituer les conditionneurs chimiques par des produits naturels d’origine végétale.

Mots-clés :

- Coagulation,

- filtration,

- Opuntia ficus indica,

- boues,

- conditionnement

Corps de l’article

1. Introduction

The sludge conditioning is usually performed using mineral salts, synthetic polymers or with the combination of the both. However, despite their proven effectiveness (BOLTO et al., 2007; KRISHNAMURTHY et al., 2005), the chemical conditioning has some disadvantages for human health and ecosystems (LU, 2002; SEPÙLVEDA et al., 2007). To solve this problem, these last few years, another kind of natural reagent has been found. These "green chemicals" have the advantages of being biodegradable and without risk to the public health. The recent literature, indicates the use of coagulant flocculants issued from vegetable, animal or micro-organism are used in the treatment of natural water and waste water. Among these natural coagulants, Moringa oleifera is certainly the most studied by the scientific community since that its coagulant properties have been recognized (YIN, 2010). Since 1999, the coagulation abilities of the cactus are highlighted (DIAZ et al., 1999). The different species of Opuntia are habitually used for human food, fodder, medicine and cosmetics (SÀENZ et al., 2004), recently, the interest of researchers in the field of the water treatment aroused. The cactus Opuntia ficus indica is native of South America, but it is also found in the arid and semi-arid regions in Africa and Australia as well as in the south of Europe and Asia. The family of cactaces is known for its production of the mucilage. The mucilage is mainly composed of galacturonic acid and different quantities of L-arabinose, D-galactose, L-rhamnose, and D-xylose (TRACHTENBERG et al., 1982) in addition to the dietary fiber and other mineral elements such as Ca2+ and K+ whose presence is necessary for the gelatinous properties of mucilage (WONLY et al., 2008). The extraction of the cactus mucilage is done by mixture of water and different organic solvents such as ethanol, acetone and methanol.

In this work, the OFIJ which is widely available in the Algerian territory (North of Africa) is extracted, characterized, and then used in the sludge conditioning experiments. Its coagulant performances are compared to those of cationic, anionic and non-ionic commercial polymers, aluminum sulfate and ferric chloride. The sludge conditioning is followed by dehydration and the following parameters are determined: specific resistance to filtration (SRF), turbidity and dryness are studied during a vacuum filtration.

2. Materials and methods

2.1. Coagulants

The Opunitia ficus indica used in this study was from Boufarik area (North of Algeria). The cladodes were picked on March 2013 and transported immediately to the laboratory to be used for the juice extraction. For comparison purposes, the wastewater treatment sludge is also conditioned with three synthetic polymers Chimfloc C4346, Sedipur NF400 and Sedipur AF102 (cationic, no-ionic and anionic, respectively) from Cosme Company.

2.2 Sludge sampling and conditioning

The stabilized sludge is sampled from the Beni-Messous wastewater treatment plant (WWTP) which is located at 15 km of the West of Algiers. The samples are stored in obscurity at 4°C. The sludge collected from the WWTP is passed through a 4.25 mm sieve to remove any gross-sized particles. 500 ml sample of the sludge is poured into a 1000 ml beaker, and the required dosages of conditioners are added. The sludge and conditioner are rapidly mixed using the Jar test apparatus (Stuart Floculator SW6) at 120 rpm for 20 s, followed by gentle flocculation at 40 rpm for 2 min. To assess the coagulation/flocculation effectiveness, a vacuum filtration is conducted on conditioned sludge at the negative pressure of 0.06 MPa. The measurement set is consisting of 7 cm diameter Buchner funnel, membrane of 8 µm pore size, vacuum pump, and graduated measuring cylinder where the filtrate is collected. The parameters assessed after the dewatering process are the specific resistance of filtration (SRF) and the dryness of the filtration cake, and turbidity, conductivity, and zeta potential of the filtrate.

3. Results and discussion

3.1 Turbidity

Figure 1 shows the obtained results concerning the effects of the conditioners doses of Chimfloc C4346, Sedipur AF102, Sedipur NF400 and OFIJ (ranged from 0.2 to 3 g⋅kg‑1 of dry matter), FeCl3 and Al2(SO4)3 (ranged from 10 to 100 g⋅kg‑1) on the filtrate turbidity after the vacuum filtration.

Figure 1

Effect of various doses of (a) OFIJ and polymers, (b) FeCl3 and Al2(SO4)3 on the filtrate turbidity

Effet de la variation de la concentration de (a) OFIJ et polyélectrolyte, (b) sels minéraux sur la turbidité du filtrat

3.2 Dryness

Figure 2 shows the variation of the cake dryness. The cake is formed during the vacuum filtration. It could be seen that an increase in conditioners dosages produces an increase in the dryness of the filtration cake except for the anionic polymer Sedipur AF102 for which there is a decrease of the dryness. Further, for the concentration of 19 g⋅kg‑1 of dry matter, the dryness increased.

Figure 2

Effect of various doses of (a) OFIJ and polymers, (b) Al2(SO4)3 and FeCl3, on the dryness

Effet de la variation de la concentration de (a) OFIJ et polyélectrolyte, (b) sels minéraux sur la siccité du gâteau de filtration

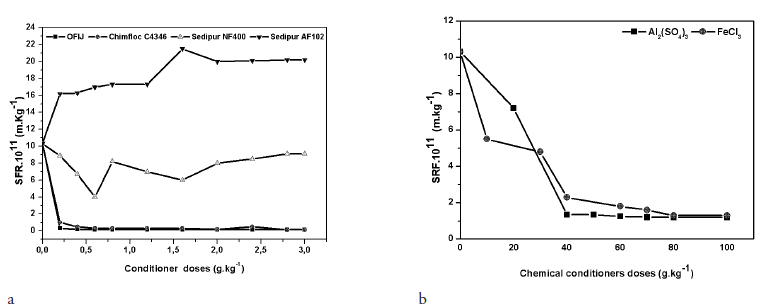

3.3. Specific resistance of filtration (SRF)

The relationship between conditioners dosage and the SRF is shown in figure 3. It could be seen from the figure 3 (a) the best reduction of SRF is assigned to the plant material, since it reached the value of 1.6⋅1011 m⋅kg‑1 for a concentration of 0.4 g⋅kg‑1 (Figure 3 (a)), the anionic polymer Sedipur AF102 caused an increase in the RSF value which is due to the formation of a viscous layer on the filter.

Figure 3

Effect of various doses of (a) OFIJ and polymers, (b) Al2(SO4)3 and FeCl3, on the specific resistance to filtration (SRF)

Effet de la variation de la concentration de (a) OFIJ et polyélectrolyte, (b) sels minéraux sur la résistance spécifique à la filtration (RSF)

From Figure 3 (b), it could be noted that the SRF value of 1.3⋅1011 m⋅kg‑1 is reached for aluminum sulfate and ferric chloride dosages of 40 and 80 g⋅kg‑1, respectively.

More the coagulants doses increase more the cake obtained after filtration will be dry, consisting, porous and less resistant to the filtration so the results obtained of RSF closely mirror those of dryness, indicating a correlation between RSF, dryness and residual turbidity of the filtrate. Table 1 presents comparative results of all conditioners in residual turbidity, dryness and SRF with their optimum dosage value. All the results indicate that OFIJ acts like cationic polymer Chimfloc C4346 although its charge surface is negative due to the sludge’s pH.

Table 1

Comparison of the optimal doses and efficiency of the different conditioners

Comparaison des doses optimales et de l’efficacité des différents conditionneurs

3.4. Mechanism

The four coagulation flocculation mechanisms are charge neutralization, sweep flocculation, adsorption and bridging of particles and double layer compression. The measurement of zeta potential and conductivity (Figure 4) suggest that the most probably mechanism is the adsorption and bridging of particles because despite increasing the OFIJ added to the sludge, zeta potential of filtrate still negative which excludes the thesis of charges neutralization and sweep flocculation. Conductivity is constant that suggests the absence of ions able to compress double layer and cause the coagulation. MILLER et al. support the hypothesis that particles do not directly contact one another but are bound to a polymer-like material from Opuntia. It is probably that natural electrolytes from within the Opuntia pad, particularly the divalent cations, which are known to be important for coagulation with anionic polymers, facilitate adsorption.

Figure 4

Variation of zeta potential and conductivity

Variation du potentiel zêta et de la conductivité

Conclusion

This study is conducted to determine the OFIJ ability as a natural flocculent for the WWTP sewage sludge conditioning. The performed experiments show that the juice of cactus has improved the coagulation/flocculation of almost all of the sludge, and making liquid-solid separation easy before using a filtration process free of big flocs. The residual turbidity, the SRF, and the dryness obtained are the same of those obtained using Chimfloc C4346 and better than those obtained with Sedipur NF400 Sedipur AF102 and inorganic chemicals. Relying on these results, the OFIJ could be used as a natural conditioner in sewage sludge treatment.

Parties annexes

References

- BOLTO, B. and J. GREGORY (2007). Organic polyelectrolytes in water treatment. Water Res., 41, 2301-2324.

- DIAZ, A., N. RINCON, A. ESCORIHUELA, N. FERNANDEZ, E. CHACIN and C.F. FORSTER (1999). A preliminary evaluation of turbidity removal by natural coagulants indigenous to Venezuela. Process Biochem., 36, 391-395.

- KRISHNAMURTHY, S. and T. VIRARAGHAVAN (2005). Chemical conditioning for dewatering municipal wastewater sludges. Energ Source., 27,113-122.

- LU, Z. (2002). Medicament of water treatment. Publishing Company of Chemical Industry, Beijing., 100-102.

- MILLER, S.M., E.J. FUGATE, V.O. CRAVER, J.A. SMITH and J.B. ZIMMERMAN (2008). Toward understanding the efficacy and mechanism of Opuntia spp. as a natural coagulant for potential application in water treatment. Environ Sci Technol., 42, 4274–9.

- SAENZ, C., E. SEPULVEDA and B. MATSUHIRO (2004). Opuntia spp mucilage’s: a functional component with industrial perspectives. J. Arid Environ., 57, 275-290.

- SEPULVEDA, E., C. Saenz, E. Aliaga, and C. Aceituno (2007). Extraction and characterization of mucilage in Opuntia spp. J. Arid Environ., 68, 534-545.

- TRACHENBERG, S. and A.M. MAYER (1982). Biophysical properties of Opuntia ficus-indica mucilage. Phytochem., 21, 2835-2843.

- WOLNY, L., P. WOLSKI and I. ZAWIEJA (2008). Rheological parameters of dewatered sewage sludge after conditioning. Desalination, 222, 382–387.

- YIN, C.Y. (2010). Emerging usage of plant-based coagulants for water and wastewater treatment. Process Biochem., 45, 1437-1444.

Liste des figures

Figure 1

Effect of various doses of (a) OFIJ and polymers, (b) FeCl3 and Al2(SO4)3 on the filtrate turbidity

Effet de la variation de la concentration de (a) OFIJ et polyélectrolyte, (b) sels minéraux sur la turbidité du filtrat

Figure 2

Effect of various doses of (a) OFIJ and polymers, (b) Al2(SO4)3 and FeCl3, on the dryness

Effet de la variation de la concentration de (a) OFIJ et polyélectrolyte, (b) sels minéraux sur la siccité du gâteau de filtration

Figure 3

Effect of various doses of (a) OFIJ and polymers, (b) Al2(SO4)3 and FeCl3, on the specific resistance to filtration (SRF)

Effet de la variation de la concentration de (a) OFIJ et polyélectrolyte, (b) sels minéraux sur la résistance spécifique à la filtration (RSF)

Figure 4

Variation of zeta potential and conductivity

Variation du potentiel zêta et de la conductivité

Liste des tableaux

Table 1

Comparison of the optimal doses and efficiency of the different conditioners

Comparaison des doses optimales et de l’efficacité des différents conditionneurs