Résumés

Abstract

Settling is one of the processes occurring in waste stabilization ponds (WSP). Part of suspended solids (SS) is removed by sedimentation but very often the efficiency of WSP is presented without making a difference between settling and biological processes. In this way the WSP is seen as a black box process. This work presents an experimental approach to the study of the removal of wastewater suspended solids in a test column in order to improve our knowledge of the settling process in ponds. These results show that the settling test in columns can be used to estimate the half removal time (t50) for the study of settling characteristics of suspended solids in wastewater stabilization ponds.

The aim of this study was to determine the half removal time (t50) in anaerobic, facultative and maturation ponds, and in the influent to these ponds, at the experimental wastewater treatment plant of CERTE (Recycling and Treatment Center of Wastewater in Tunisia), by a column settling test. The experiments lasted between 15 and 120 min. The column was 2 m high with sampling systems at various depths: 40, 80, 120, 160 and 200 cm. Half-removal suspended solids time t50 was defined as the time at which 50% of SS was removed. Models derived from the scientific literature were used to interpret the experimental data. The experimental results demonstrated that higher suspended solids concentrations in the influent led to shorter t50 values and better settling.

Keywords:

- half removal time,

- settling column,

- suspended solids,

- stabilization ponds,

- anaerobic ponds

Résumé

En lagunage le processus de décantation des matières en suspension constitue un des mécanismes du traitement. Une partie des matières en suspension (MES) est éliminée par sédimentation. Cependant, les rendements des installations sont souvent présentés sans faire la distinction entre la sédimentation et les processus biologiques. En ce sens la lagune est vue comme une boîte noire, et il paraît important de mieux chiffrer la contribution de la décantation sur le rendement global.

Ce travail présente une approche expérimentale de l’étude de l’élimination des matières solides dans les eaux usées par le biais d’un test réalisé dans une colonne de décantation en vue de mieux comprendre et d’améliorer les processus de décantation dans les bassins. L’objectif de cette étude était de déterminer le temps de demi-décantation (t50) au moyen d’essais de décantation en colonne sur des échantillons prélevés dans les lagunes anaérobies, facultatives, de maturation ainsi que dans l’influent de la station expérimentale des eaux usées domestiques du CERTE en Tunisie. Ces essais ont permis de déterminer le t50, qui représente le temps de décantation au bout duquel nous observons 50 % d’élimination des matières en suspension. La colonne utilisée a 2 m de hauteur et est munie d’un système d’échantillonnage à différentes profondeurs : 40, 80, 120, 160 et 200 cm. Les temps de prélèvement sont de 15, 30, 45, 60, 75, 90, 105 et 120 min. Des modèles décrits dans la littérature scientifique ont été utilisés pour l’interprétation de nos résultats.

Nous constatons que dans cette station les concentrations de MES ne changent pas énormément d’un bassin à l’autre et malheureusement ne couvrent pas la gamme des matières en suspension (MES) dans ce type de bassin. Ce sont des eaux plus riches en matières colloïdales qu’en matières solides. Les temps correspondant à 50 % d’élimination calculés selon la méthode de KRISHNAN sont proches de ceux déterminés graphiquement selon la méthode de TAY. Cela suppose que 50 % d’élimination des MES peuvent être obtenus dans la colonne entre 71 et 135 min pour les eaux issues des différents bassins, avec à peu près la même composition d’eau usée. La plus faible valeur de t50 (14 min) est obtenue dans le cas du mélange « surnageant plus sédiment » de la lagune anaérobie avec une concentration élevée en MES.

Ainsi, les résultats expérimentaux obtenus montrent que t50 sera d’autant plus petit que la concentration des matières en suspension dans l’influent est élevée, ce qui induit une meilleure décantation. Ces résultats illustrent bien le fait que les essais de décantation en colonne peuvent être utilisés pour estimer le t50 en ce qui concerne l’étude des caractéristiques des suspensions solides dans les systèmes d’épuration des eaux usées. Les étapes suivantes devront porter sur le passage des résultats en colonne aux valeurs utilisables en vraie grandeur.

Mots-clés :

- colonne de décantation,

- matières en suspension,

- temps de demi-élimination,

- lagunage,

- lagunage anaérobie

Corps de l’article

1. Introduction

In hot climates stabilization ponds are often used for wastewater treatment. When the temperature is favourable, anaerobic ponds may be built in the first part of the treatment plants. In this case anaerobic ponds act also as primary settlers where it is well known that the main process is flocculent settling. Settling will also occur in the other ponds but the characteristics of the particles are different. Settling processes in ponds, at least in anaerobic ponds, can be considered as flocculent sedimentation. Due to the various particle sizes, Stokes velocities of large particles are higher than for small ones. This may produce collisions inducing flocculation which, in turn, will yield larger flocs, and thus particles settle faster. The consequence is that the settling velocity is not constant and the residence time in the settler has an effect on the efficiency of the system. This is an important difference with the sedimentation of monodisperse particles where the main design parameter of the system is not the volume (residence time) but the settling area.

Sedimentation tanks are key primary processes in the removal of pollutants in sewage, and current design principles, based upon empirically derived surface loading rates, have remained unchanged for years (BECKER et al., 1996). Settling of particulate material in raw wastewater is one of the main processes to remove organic material from the liquid phase in conventional waste stabilization pond (WSP) systems. In a typical configuration of conventional WSP (anaerobic + facultative + maturation ponds), suspended matter is partly eliminated in every pond. Thus the retention time in each pond is important for the settling process, especially in anaerobic ponds where most of sedimentation occurs. However, except in the study by TAY (1982) on domestic wastewaters with and without chemical addition, little work has been done to evaluate the settling characteristics of solids in ponds. TAY studied the settling performance and the hydraulic behaviour of primary settling tanks at three Ontario domestic wastewater treatment plants located in Sarnia (SS = 124 mg•L‑1), Windsor (SS = 102 mg•L‑1) and Burlington (SS = 220 mg•L‑1) by settling column tests. The half removal times were quite similar for the three plants. He obtained t50 = 53 min for the test without chemical addition. Optimum chemical dosages were about the same: 17 mg•L‑1 of FeCl3 (as Fe3+) was added at Sarnia and Windsor and 18 mg•L‑1 at Burlington for t50 = 17 min. The polymer dose was 0.3 mg•L‑1 for all three plants and he obtained t50 values of 6 min.

Accordingly, the work presented here assesses the settling characteristics in various ponds by column experiments, as in TAY (1982). Settling trials in columns were performed on water from existing ponds: anaerobic, facultative, maturation ponds, as well as on the influent. Mixed water was also prepared with liquid and sediments from the anaerobic pond. These experiments were designed to:

Check if flocculent settling models can be applied to various types of pond waters.

Determine the half removal time in batch mode for various types of pond waters.

Ultimately the model should facilitate the calculation of SS removal efficiencies on full scale facilities.

2. Materials and methods

2.1 Geometric characteristics of the ponds

This study deals with the experimental waste stabilization pond system belonging to CERTE (Recycling and Treatment Center of Wastewater in Tunisia). Domestic wastewater is pumped from the main sewerage network of Tunis City to the experimental wastewater treatment plant of CERTE. This plant has been in operation since 1992. The water is partly settled in a small primary settling tank and is then distributed into the ponds.

The studied wastewater treatment system consists of four ponds connected in series: an anaerobic pond, followed by a facultative pond and two maturation ponds. This plant receives a BOD5 mass load of 9.3 kg BOD5•d‑1, a SS mass load of 5 kg SS•d‑1 and an inlet flow of 35 m3•d‑1. During the time of experiment, these loads and flow rates remained nearly constant. The removal efficiencies of this plant are 36, 47 and 70% respectively for SS, raw COD and raw BOD, for a theoretical total residence time of 16.8 days. A layout of the waste stabilization pond system is presented in Figure 1 and the characteristics are given in Table 1.

Figure 1

Layout of wastewater settling ponds (WSP) at the CERTE experimental plant in Tunisia (water was sampled at the inlet of each pond).

Plan de la station expérimentale du CERTE en Tunisie.

Table 1

Main dimensions of ponds (GHRABI, 1994).

Dimensions principales des bassins (GHRABI, 1994).

2.2 Experimental set-up and methodology

Water was sampled within these ponds as mentioned in Figure 1 at points I, II, III and IV respectively for ponds 1, 2, 3 and 4. The water was pumped directly from a pond into the test column by a centrifugal pump, except for the mixture of sediments and water that was prepared outside of the pond. After filling, the mixture was remixed rapidly to get a constant SS concentration in the column. Determination of the suspended solids settling characteristics of pond water was carried out in a 2 m high and 20 cm diameter settling column (total volume of 62.8 L), equipped with sampling systems at various depths: 0, 40, 80, 120, 160 and 200 cm (Figure 2). We sampled (20 or 50 mL) at each level (from top to bottom) at predetermined times (15-30-45-75-90-105-120 min). Suspended solids in the samples were analyzed according to STANDARD METHODS (1998). The sample volume (20 or 50 mL) was selected from expected results to get the best measurement accuracy. Mixed water was prepared with liquid (2/3) and sediments (1/3) from the anaerobic pond. This special test was done to evaluate the settling properties of sediments accumulated in the ponds. In fact, those sediments can be resuspended by various processes: biogas production, mixing, pumping, etc. From the test we can deduce that the settling properties of these sediments are good and even if some resuspension occurs it should not last for a long time. Sediment analysis indicates that these suspended solids do not have an important organic matter (51.3%) content, indicating that a rather high mineral load arrives at this wastewater treatment plant.

Figure 2

Diagram of the settling column

Schéma de la colonne de décantation.

KRISHNAN’s method (1976) was applied to the experimental data. This method considers that at each time value (θ) there corresponds a hydraulic load (Ch) equivalent to the upward velocity which would permit to fill the entire column during time (θ). The expression of the hydraulic load (Ch) is given by equation 1:

where θ is the sampling time and H is the column height. Accordingly we can construct a removal graph which represents the percentage of the matter removed versus the hydraulic load or upward velocity (Ch).

This is one of the usual methods used to assess the settling performance of flocculent suspensions as no fully deterministic mathematical model is available, as in the case of independent particles. In these semi-empirical methods, it is assumed that settling in the column represents the phenomenon taking place in a vertical section of water moving in the settler between the inlet and the outlet. This is the reason why the experimental column has to have the same height as the settling compartment. In this preliminary study we did not modify the depth of the test column to be sure that the half removal times would not depend on this additional factor.

We also applied TAY’s model (1982), described by the following equations:

Equation 2 can be rewritten as follow:

where S0 and S are concentrations of suspended solids (mg•L‑1) respectively at to and at time θ and t50 is the half removal time (min), the time needed to get 50% removal. It is the only parameter of the model. Equation 3 can be fitted by plotting ((S0/S)‑1) versus θ. The slope of this straight line is equal to (1/t50).

In fact, TAY’s model is an empirical model, but if we assume that the process is flocculent settling, this equation can be obtained from equation 4, which is an equation describing perikinetic flocculation (TAY, 1982).

3. Results and discussion

The concentrations of suspended solids for each level of the column are given in Table 2; these values correspond to the case of the anaerobic pond (liquid of the pond previously mixed with sediment). For all settling column tests on the various ponds, the principle remains the same - as time increases, the particles move to the bottom of the column. Accordingly, the SS concentrations in the lower layers of the column are increasing. An example is provided on Figure 3 (pond liquid mixed with sediment).

Table 2

Suspended solids values at each settling time and for each layer of the settling column (case of anaerobic pond: pond liquid mixed with sediment).

Valeurs des matières en suspension à chaque temps et pour chaque tranche de décantation de la colonne (cas de la lagune anaérobie : mélange du surnageant liquide et des sédiments).

Figure 3

Evolution of suspended solids versus settling time (case of anaerobic pond: liquid mixed with sediment, S0 = 2,880 mg•L-1).

Évolution des matières en suspension en fonction du temps de décantation (cas d'étude de la lagune anaérobie : mélange surnageant plus sédiment, S0 = 2 880 mg•L-1).

The percentage of suspended solids removal (SS%) in Table 2 is calculated according to equation 5:

where S0 is the initial SS concentration and Saverage is the average concentration of suspended solids calculated at each time. As the average is calculated from the measurements at each level, it is important to have a constant distance between sampling points to get a correct “weighted” average.

Accordingly to Krishnan’s method and Tay’s model described above, we determined the half removal times. Examples are provided on Figures 4 and 5 in the case of the anaerobic pond (pond liquid mixed with sediment) and Table 3 provides the values of t50 for the other ponds. As can be seen in Figure 5, Tay’s model fits well here with R2 = 0.94. Here the t50 corresponds to the time needed to remove 50% of suspended solids obtained by interpolation of experimental values according to Krishnan’s method. The overall removal time (calculated according to Krishnan’s method) for the different ponds is close to t50 values (obtained by Tay’s graphical method). The only exception is for raw wastewater (liquid): the obtained value is large (135 min) compared to the 60 min obtained by Krishnan’s method.

Figure 4

Suspended solids removal versus upward velocity in the different ponds.

Élimination des matières en suspension en fonction de la vitesse ascensionnelle dans les différents bassins.

Figure 5

Interpretation of data from Table 2 by TA Y's model (anaerobic pond (mixed liquid + sediment), t50 =14 min).

Interprétation des données du tableau 2 par le modèle de TAY (cas d’étude de la lagune anaérobie : mélange surnageant plus sédiment, t50 = 14 min).

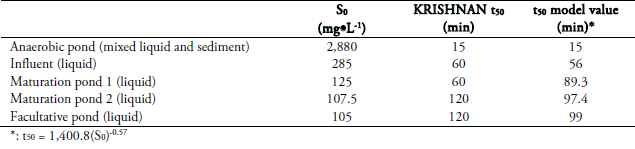

Table 3

Comparison of half removal time in each pond.

Comparaison dans chaque bassin du temps correspondant à 50 % d'élimination.

Table 3 provides the results obtained on inlet waters and waters from the various ponds. A good fit is usually obtained with Tay’s model as all R2 values are between 0.51 and 0.95. As expected, t50 values are not constant and range from 71 to 135 min because wastewater contains much higher colloid matter than suspended solids and also because of rain water which can dilute them. The t50 values for the mixture of sediments and anaerobic water were much shorter (14 min).

WILL and DAVIS (1962) studied the hydraulic behaviour of full scale primary settling tanks by tracer studies combined with settling characterization of the wastewater by column tests. The raw wastewater was mainly domestic with initial average suspended solids concentrations of 276 mg•L‑1. They obtained a half removal time value of 33 min. As can be seen, our values of t50 are different due to the various characteristics of wastewater (i.e., initial concentrations). In a similar study with influent suspended solids in the range 500 to 12,500 mg•L‑1 from ponds treating starch industry effluents in Thailand, BINOD (2004) obtained half removal times of 40 and 9 min respectively, but with much higher concentrations than in our case.

Figure 6 shows the relation between the half removal times (Tay’s model) and initial concentrations of suspended solids as obtained during this study: at higher initial SS concentrations, the half removal times are shorter. In our case the half removal times plotted versus the initial concentrations of suspended solids can be estimated by the following relation fitted to the data presented in Table 4.

with R2 = 0.91. Higher SS concentrations and the corresponding settling velocities result in shorter half removal times. The last point (S: 2,880 mg•L‑1 and t: 15 min) corresponds to a hindered type settling (KYNCH’s model) (KYNCH, 1952). If this point is considered as an outlier, the regression on the remaining points provides similar results. Table 4 showed that the values of half removal time obtained experimentally during this study are close to those of the model corresponding to equation 6.

Figure 6

Half removal time versus initial suspended solids concentrations of the different ponds.

Temps correspondent à 50 % d'élimination en fonction des concentrations des matières en suspension initiales dans chaque lagune.

Table 4

Comparison of settling model and performance of the settling column test.

Comparaison du modèle de décantation et performance du test de décantation en colonne.

4. Conclusions

Very few studies have investigated the efficiency of the settling process in waste stabilization ponds, especially in anaerobic ponds. We can imagine that anaerobic ponds function similarly to primary settling tanks but the settling characteristics of the water from other ponds could be quite different. This study essentially focused on the half removal times determined from settling column tests on waste stabilization ponds waters. The system studied has been operating in CERTE - Tunisia for some years and can be considered “at steady state”. It was selected because of the presence of an anaerobic pond and because average temperature is considered as typical of hot climates.

We observed that Krishnan and Tay’s models fit well with the experimental data and that half removal times could be determined from settling columns experiments. In this plant, the SS concentrations did not change drastically from one pond to another and unfortunately did not cover the full range found for SS in ponds of this type. The experimental half removal times in the CERTE plant were in the range 71 to 135 min for the various ponds, with a tendency to increase between the inlet and the outlet of the plant. A shorter t50 (14 min) is obtained with a mixture of liquid and sediment of anaerobic pond, i.e., with higher concentrations. From our experiments, we suggest a relationship between t50 and initial SS.

The direct use of these t50 values to interpret the global settling efficiency of the pond would yield higher efficiencies than observed, since the water residence time in the ponds is usually some days and thus S/So is less than 0.1 in equation 1. This confirms that ponds are not very efficient primary settlers, and that corrections to the settling model should be related to the knowledge of the hydrodynamic patterns in the pond. We have now to combine hydrodynamic models of ponds together with fluxes due to resuspension of sediments to get a realistic model of the settling efficiencies and solid mass balances in ponds.

Modelling of the biological processes in stabilization ponds in general, and especially in anaerobic ponds, would greatly benefit from a rational approach integrating the exact contribution of the settling process in the performances of those systems. We suggest here an experimental approach to assess the settling characteristics of those waters. The next step will be to extrapolate the results of the test to quantify the performances of full scale facilities. Those steps are important milestones needed for a comprehensive approach to estimate accumulation rates and the contribution of the sediment compartment in the biological processes occurring in pond systems.

Parties annexes

Bibliographical references

- BECKER F.A., P.D. HEDGES and R.P.M. SMISSION (1996). The distributions of chemical constituents within the sewage settling velocity grading curve. Water Sci. Technol., 33, 143-146.

- BINOD K. (2004). Modelling of anaerobic treatment of wastewater in ponds. PhD thesis, School of Environment, Resources and Development, Asian Institute of Technology, Thailand, 151 p.

- GHRABI A. (1994). Traitement des eaux usées par lagunage naturel à microphytes : adaptation d’un pilote semi-industriel en condition climatique tunisienne. Thèse de Doctorat, Univ. Montpellier II, France, 210 p.

- KRISHNAN P. (1976). Column settling for flocculant suspension, discussion. J. Environ. Eng. Div.(ASCE), 102, 227-229.

- KYNCH G.J. (1952). Atheory of sedimentation. Trans.Farad. Soc., 48, 166.

- STANDARD METHODS FOR THE EXAMINATION OF WATER AND WASTEWATER (1998). 20th edition. American Public Health Association / American Water Works Association / Water Environment Federation, Washington, DC, USA.

- TAY J.H. (1982). Development of a settling model for primary settling tanks. Water Res., 16, 1413-1417.

- WILL R.F. and C. DAVIS (1962). Flow pattern in a rectangular sewage sedimentation tank. In: 1st International Conference on Water Pollution Research, Westminster, London, UK, pp. 335-385.

Liste des figures

Figure 1

Layout of wastewater settling ponds (WSP) at the CERTE experimental plant in Tunisia (water was sampled at the inlet of each pond).

Plan de la station expérimentale du CERTE en Tunisie.

Figure 2

Diagram of the settling column

Schéma de la colonne de décantation.

Figure 3

Evolution of suspended solids versus settling time (case of anaerobic pond: liquid mixed with sediment, S0 = 2,880 mg•L-1).

Évolution des matières en suspension en fonction du temps de décantation (cas d'étude de la lagune anaérobie : mélange surnageant plus sédiment, S0 = 2 880 mg•L-1).

Figure 4

Suspended solids removal versus upward velocity in the different ponds.

Élimination des matières en suspension en fonction de la vitesse ascensionnelle dans les différents bassins.

Figure 5

Interpretation of data from Table 2 by TA Y's model (anaerobic pond (mixed liquid + sediment), t50 =14 min).

Interprétation des données du tableau 2 par le modèle de TAY (cas d’étude de la lagune anaérobie : mélange surnageant plus sédiment, t50 = 14 min).

Figure 6

Half removal time versus initial suspended solids concentrations of the different ponds.

Temps correspondent à 50 % d'élimination en fonction des concentrations des matières en suspension initiales dans chaque lagune.

Liste des tableaux

Table 1

Main dimensions of ponds (GHRABI, 1994).

Dimensions principales des bassins (GHRABI, 1994).

Table 2

Suspended solids values at each settling time and for each layer of the settling column (case of anaerobic pond: pond liquid mixed with sediment).

Valeurs des matières en suspension à chaque temps et pour chaque tranche de décantation de la colonne (cas de la lagune anaérobie : mélange du surnageant liquide et des sédiments).

Table 3

Comparison of half removal time in each pond.

Comparaison dans chaque bassin du temps correspondant à 50 % d'élimination.

Table 4

Comparison of settling model and performance of the settling column test.

Comparaison du modèle de décantation et performance du test de décantation en colonne.